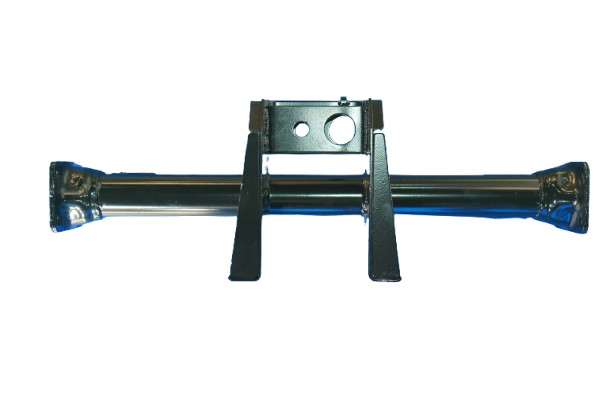

At Gloria Engineering Industries, we specialize in the production of dead axle beams for trailers, a critical component that requires precision engineering and robust construction. Our production process involves several key steps to ensure the highest quality and performance.

The production of dead axle beams begins with machining, where raw materials are precisely shaped and sized to meet specific design requirements. Using advanced CNC machining centres, we achieve exact tolerances and surface finishes that are essential for the proper functioning of the axle beams. This ensures that the beams can withstand the heavy loads and stresses encountered during trailer operation.

Next, we utilize saw welding (Submerged Arc Welding) to join the various components of the axle beam. This welding technique is ideal for producing strong, durable welds that can handle the mechanical stresses of trailer use. Our experienced welders ensure that each weld is performed with precision, resulting in a structurally sound and reliable axle beam.

Following the welding process, we conduct boring operations to create the necessary holes and cylindrical shapes within the axle beam. This step is crucial for ensuring the proper fit of bearings, bushings, and other components. Our boring machines are capable of achieving high levels of accuracy, ensuring that each axle beam meets the required specifications for assembly and operation.

Throughout the entire production process, we maintain rigorous quality control measures. Each dead axle beam undergoes thorough inspection and testing to ensure it meets industry standards and client specifications. Our commitment to quality ensures that our axle beams provide reliable performance and long service life in demanding trailer applications.

By leveraging our expertise in machining, welding, and boring, Gloria Engineering Industries delivers top-quality dead axle beams that contribute to the safety and reliability of trailers on the road.

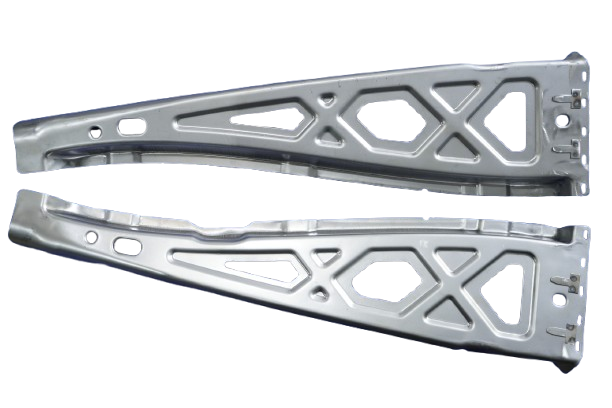

Gloria Engineering Industries is a trusted supplier of Body-in-White (BIW) parts for the TML Winger vehicle, providing critical structural components that form the backbone of the vehicle’s body. Our expertise in manufacturing complex assemblies ensures that each part meets the stringent quality and safety standards required in the automotive industry.

The A Pillar is a crucial vertical support structure located on either side of the windshield. It plays a key role in maintaining the structural integrity of the vehicle’s cabin, particularly during impacts. We manufacture A Pillars with high precision, ensuring they are strong and capable of supporting the roof and absorbing impact forces in the event of a collision.

The B Pillar is another vital structural component, positioned between the front and rear doors. It supports the roof and contributes to the overall rigidity of the vehicle’s frame. Our B Pillars are engineered to provide maximum strength and stability, contributing to the safety and durability of the TML Winger.

The Front Structure Assembly is a complex component that includes various parts such as the radiator support, bumper reinforcements, and other structural elements at the front of the vehicle. This assembly is critical for protecting the vehicle’s engine and other key components during a collision. We ensure that each front structure assembly is precisely manufactured to fit perfectly within the vehicle’s design, providing optimal protection and performance.

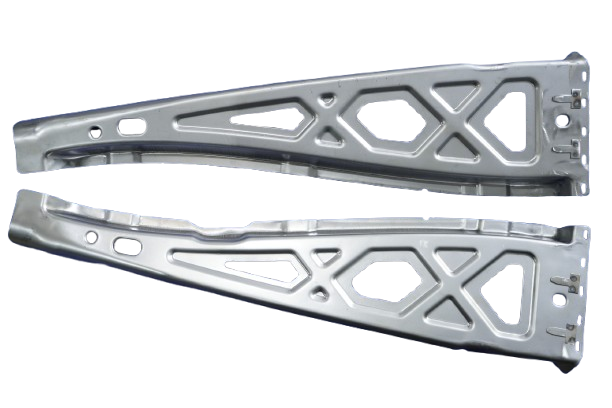

The Shotgun Assembly refers to the horizontal structural elements that run along the sides of the vehicle, typically near the front fenders. These components are crucial for reinforcing the vehicle’s structure and distributing impact forces in the event of a collision. Our shotgun assemblies are manufactured with meticulous attention to detail, ensuring they contribute effectively to the vehicle’s overall safety and structural integrity.

By supplying these essential BIW parts, Gloria Engineering Industries plays a vital role in the production of the TML Winger, ensuring that each vehicle is built to the highest standards of safety, durability, and performance.

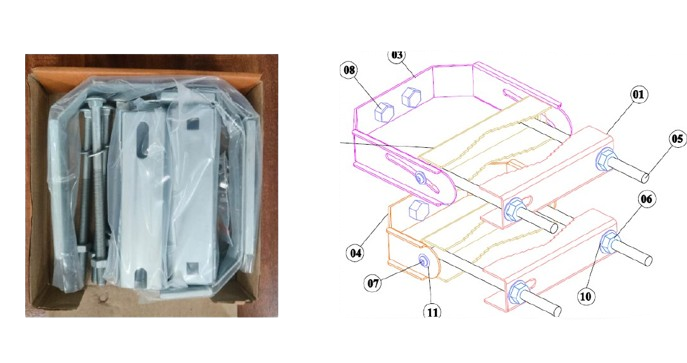

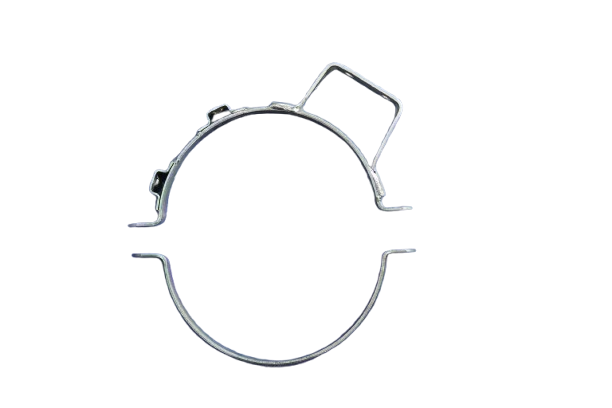

At Gloria Engineering Industries, we are proud to supply high-quality hangers and equalizer parts to York Suspension, a leading name in the heavy-duty vehicle suspension industry. These components are critical for the effective operation of suspension systems, ensuring stability, load distribution, and smooth operation of vehicles.

Hangers are essential components in a suspension system, serving as the mounting points for leaf springs and connecting the suspension to the vehicle’s frame. Our hangers are engineered for durability and strength, capable of withstanding the heavy loads and stresses encountered in commercial and industrial vehicles. Manufactured with precision, our hangers provide a secure and reliable connection, contributing to the overall performance and safety of the suspension system.

Equalizer parts play a key role in distributing the load evenly across the axles, ensuring balanced weight distribution and reducing wear on tires and suspension components. Our equalizer parts are designed to provide optimal performance in various operating conditions, enhancing the stability and longevity of the suspension system. By using high-grade materials and advanced manufacturing techniques, we ensure that these parts meet the rigorous demands of heavy-duty applications.

By supplying these critical components to York Suspension, Gloria Engineering Industries supports the production of reliable and high-performing suspension systems that contribute to the safe and efficient operation of heavy-duty vehicles on the road.

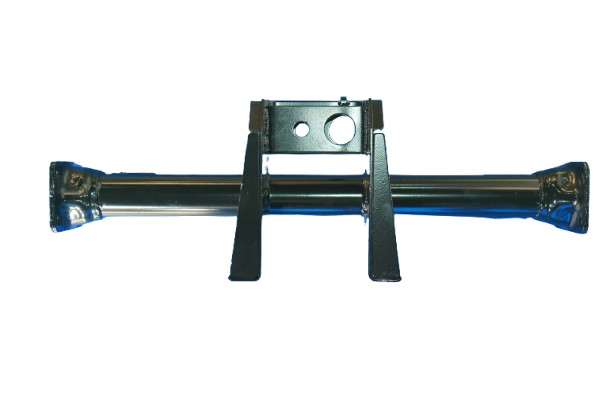

Gloria Engineering Industries is a key supplier of essential frame parts to leading automotive manufacturers TML (Tata Motors Limited) and M&M (Mahindra & Mahindra). These components are integral to the structural integrity and performance of vehicles, ensuring durability and safety.

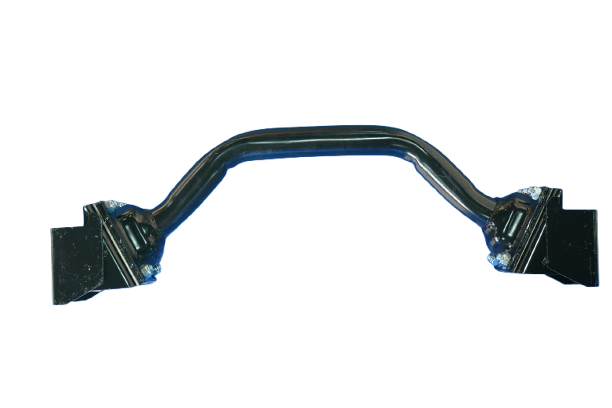

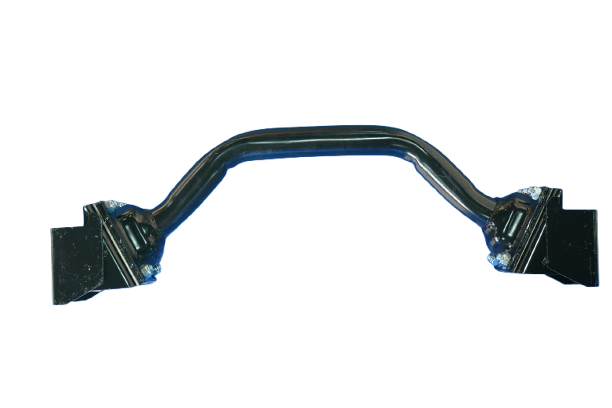

Cross members are vital structural components that connect the sides of a vehicle’s frame, providing rigidity and support. Our cross members are manufactured with precision to ensure they withstand the stresses of driving and contribute to the overall stability of the vehicle’s chassis. Whether for passenger vehicles or commercial trucks, our cross members are designed to enhance the durability and strength of the vehicle’s frame.

Reinforcements are added to various parts of the vehicle frame to strengthen areas that bear significant loads or are subject to high stress. At Gloria Engineering Industries, we produce reinforcements that are engineered to meet specific design requirements, ensuring that they effectively enhance the structural integrity of the vehicle. These components are crucial for improving the vehicle’s safety and longevity, particularly in demanding driving conditions.

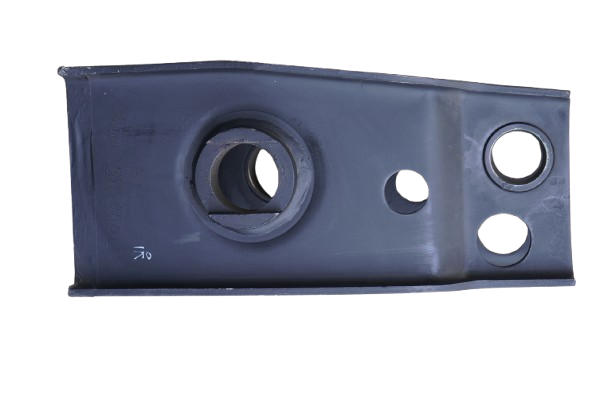

Engine mountings are critical for securely attaching the engine to the vehicle’s frame, while also absorbing vibrations and reducing noise. Our engine mountings are designed to provide a stable connection between the engine and the frame, ensuring smooth operation and minimizing wear and tear on both the engine and the vehicle’s structure. By supplying high-quality engine mountings, we help enhance the overall performance and comfort of the vehicles produced by TML and M&M.

By providing these crucial frame parts to TML and M&M, Gloria Engineering Industries plays a significant role in the production of vehicles that are not only robust and reliable but also meet the highest standards of safety and performance.

Gloria Engineering Industries is proud to supply high-quality parts for rotavators to Maschio Gaspardo, a renowned name in the agricultural machinery industry. Rotavators are essential tools in modern farming, used for soil preparation and cultivation. Our components are designed to ensure the reliability, efficiency, and durability of these machines.

We supply precision machined components that are crucial for the smooth operation of rotavators. These parts are manufactured with high accuracy to meet the stringent quality standards required for agricultural machinery, ensuring that they can withstand the harsh conditions of fieldwork and provide long-lasting performance.

Our structural parts for rotavators are built to endure the rigors of heavy-duty farming operations. These components are designed to handle the high levels of stress and wear that come with soil cultivation, ensuring that the rotavators remain sturdy and effective over time.

We also supply various assembly and sub-assembly parts that contribute to the overall functionality of the rotavators. These parts are carefully crafted to fit seamlessly into the machinery, ensuring that the rotavators operate efficiently and with minimal downtime.

By supplying these essential parts to Maschio Gaspardo, Gloria Engineering Industries supports the production of high-performance rotavators that help farmers achieve better soil preparation and higher crop yields, ultimately contributing to more efficient and productive farming practices.

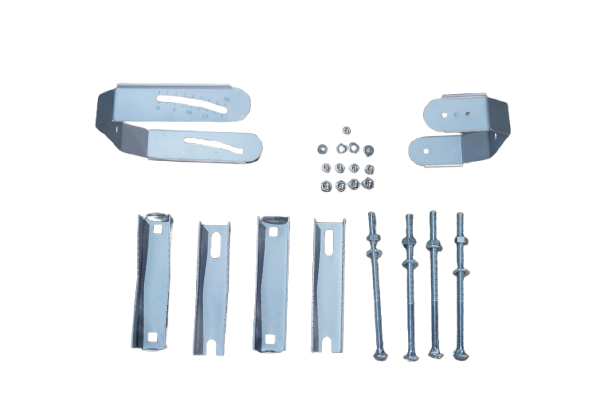

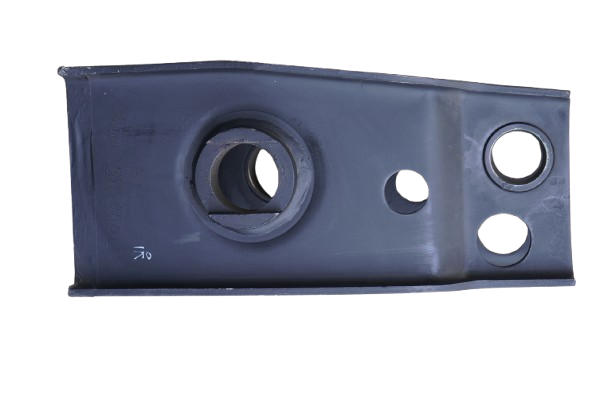

Gloria Engineering Industries is a reliable supplier of bracketry parts to leading automotive manufacturers TML (Tata Motors Limited) and M&M (Mahindra & Mahindra). These brackets are crucial for securing various components within the vehicle, ensuring stability, safety, and optimal performance.

We supply engine and transmission brackets that securely mount these critical components to the vehicle’s frame. Our brackets are designed to withstand the vibrations and stresses associated with engine and transmission operation, ensuring that these key systems remain stable and function smoothly throughout the vehicle’s life.

Our suspension and chassis brackets are engineered to provide strong and reliable support for the vehicle’s suspension system. These parts are vital for maintaining the vehicle’s ride quality and handling, as they keep the suspension components firmly in place, even under challenging driving conditions.

We also manufacture interior and exterior brackets that serve a variety of purposes, from holding interior panels and components in place to securing external parts like bumpers and lights. These brackets are crafted to ensure a perfect fit and long-lasting durability, contributing to the overall quality and appearance of the vehicle.

By supplying these essential bracketry parts to TML and M&M, Gloria Engineering Industries plays a key role in ensuring that their vehicles are built to the highest standards of quality, safety, and performance. Our commitment to precision manufacturing ensures that every bracket we produce meets the rigorous demands of the automotive industry.

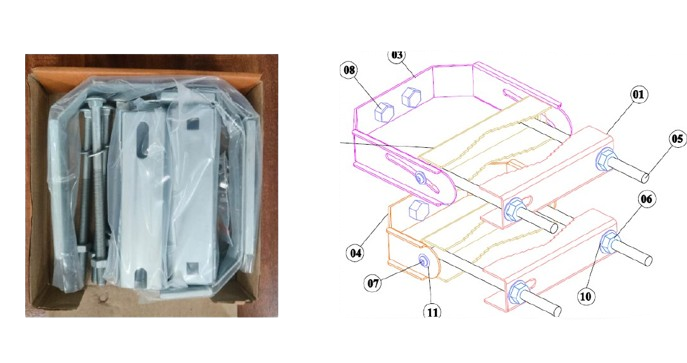

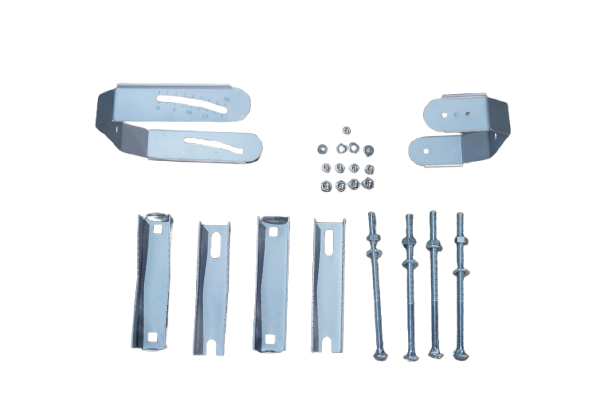

Gloria Engineering Industries is a key supplier of radio mounting brackets to Reliance, a leading company in telecommunications and electronics. These brackets are designed to securely hold radio equipment in place, ensuring reliable and efficient performance in various applications.

At Gloria Engineering Industries, we specialize in the production of dead axle beams for trailers, a critical component that requires precision engineering and robust construction. Our production process involves several key steps to ensure the highest quality and performance.

The production of dead axle beams begins with machining, where raw materials are precisely shaped and sized to meet specific design requirements. Using advanced CNC machining centres, we achieve exact tolerances and surface finishes that are essential for the proper functioning of the axle beams. This ensures that the beams can withstand the heavy loads and stresses encountered during trailer operation.

Next, we utilize saw welding (Submerged Arc Welding) to join the various components of the axle beam. This welding technique is ideal for producing strong, durable welds that can handle the mechanical stresses of trailer use. Our experienced welders ensure that each weld is performed with precision, resulting in a structurally sound and reliable axle beam.

Following the welding process, we conduct boring operations to create the necessary holes and cylindrical shapes within the axle beam. This step is crucial for ensuring the proper fit of bearings, bushings, and other components. Our boring machines are capable of achieving high levels of accuracy, ensuring that each axle beam meets the required specifications for assembly and operation.

Throughout the entire production process, we maintain rigorous quality control measures. Each dead axle beam undergoes thorough inspection and testing to ensure it meets industry standards and client specifications. Our commitment to quality ensures that our axle beams provide reliable performance and long service life in demanding trailer applications.

By leveraging our expertise in machining, welding, and boring, Gloria Engineering Industries delivers top-quality dead axle beams that contribute to the safety and reliability of trailers on the road.

Gloria Engineering Industries is a trusted supplier of Body-in-White (BIW) parts for the TML Winger vehicle, providing critical structural components that form the backbone of the vehicle’s body. Our expertise in manufacturing complex assemblies ensures that each part meets the stringent quality and safety standards required in the automotive industry.

The A Pillar is a crucial vertical support structure located on either side of the windshield. It plays a key role in maintaining the structural integrity of the vehicle’s cabin, particularly during impacts. We manufacture A Pillars with high precision, ensuring they are strong and capable of supporting the roof and absorbing impact forces in the event of a collision.

The B Pillar is another vital structural component, positioned between the front and rear doors. It supports the roof and contributes to the overall rigidity of the vehicle’s frame. Our B Pillars are engineered to provide maximum strength and stability, contributing to the safety and durability of the TML Winger.

The Front Structure Assembly is a complex component that includes various parts such as the radiator support, bumper reinforcements, and other structural elements at the front of the vehicle. This assembly is critical for protecting the vehicle’s engine and other key components during a collision. We ensure that each front structure assembly is precisely manufactured to fit perfectly within the vehicle’s design, providing optimal protection and performance.

The Shotgun Assembly refers to the horizontal structural elements that run along the sides of the vehicle, typically near the front fenders. These components are crucial for reinforcing the vehicle’s structure and distributing impact forces in the event of a collision. Our shotgun assemblies are manufactured with meticulous attention to detail, ensuring they contribute effectively to the vehicle’s overall safety and structural integrity.

By supplying these essential BIW parts, Gloria Engineering Industries plays a vital role in the production of the TML Winger, ensuring that each vehicle is built to the highest standards of safety, durability, and performance.

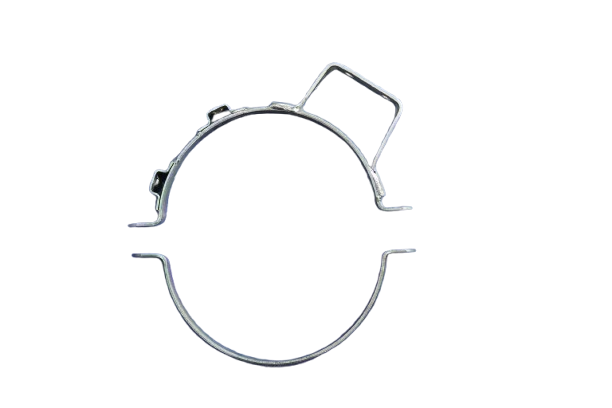

At Gloria Engineering Industries, we are proud to supply high-quality hangers and equalizer parts to York Suspension, a leading name in the heavy-duty vehicle suspension industry. These components are critical for the effective operation of suspension systems, ensuring stability, load distribution, and smooth operation of vehicles.

Hangers are essential components in a suspension system, serving as the mounting points for leaf springs and connecting the suspension to the vehicle’s frame. Our hangers are engineered for durability and strength, capable of withstanding the heavy loads and stresses encountered in commercial and industrial vehicles. Manufactured with precision, our hangers provide a secure and reliable connection, contributing to the overall performance and safety of the suspension system.

Equalizer parts play a key role in distributing the load evenly across the axles, ensuring balanced weight distribution and reducing wear on tires and suspension components. Our equalizer parts are designed to provide optimal performance in various operating conditions, enhancing the stability and longevity of the suspension system. By using high-grade materials and advanced manufacturing techniques, we ensure that these parts meet the rigorous demands of heavy-duty applications.

By supplying these critical components to York Suspension, Gloria Engineering Industries supports the production of reliable and high-performing suspension systems that contribute to the safe and efficient operation of heavy-duty vehicles on the road.

Gloria Engineering Industries is a key supplier of essential frame parts to leading automotive manufacturers TML (Tata Motors Limited) and M&M (Mahindra & Mahindra). These components are integral to the structural integrity and performance of vehicles, ensuring durability and safety.

Cross members are vital structural components that connect the sides of a vehicle’s frame, providing rigidity and support. Our cross members are manufactured with precision to ensure they withstand the stresses of driving and contribute to the overall stability of the vehicle’s chassis. Whether for passenger vehicles or commercial trucks, our cross members are designed to enhance the durability and strength of the vehicle’s frame.

Reinforcements are added to various parts of the vehicle frame to strengthen areas that bear significant loads or are subject to high stress. At Gloria Engineering Industries, we produce reinforcements that are engineered to meet specific design requirements, ensuring that they effectively enhance the structural integrity of the vehicle. These components are crucial for improving the vehicle’s safety and longevity, particularly in demanding driving conditions.

Engine mountings are critical for securely attaching the engine to the vehicle’s frame, while also absorbing vibrations and reducing noise. Our engine mountings are designed to provide a stable connection between the engine and the frame, ensuring smooth operation and minimizing wear and tear on both the engine and the vehicle’s structure. By supplying high-quality engine mountings, we help enhance the overall performance and comfort of the vehicles produced by TML and M&M.

By providing these crucial frame parts to TML and M&M, Gloria Engineering Industries plays a significant role in the production of vehicles that are not only robust and reliable but also meet the highest standards of safety and performance.

Gloria Engineering Industries is proud to supply high-quality parts for rotavators to Maschio Gaspardo, a renowned name in the agricultural machinery industry. Rotavators are essential tools in modern farming, used for soil preparation and cultivation. Our components are designed to ensure the reliability, efficiency, and durability of these machines.

We supply precision machined components that are crucial for the smooth operation of rotavators. These parts are manufactured with high accuracy to meet the stringent quality standards required for agricultural machinery, ensuring that they can withstand the harsh conditions of fieldwork and provide long-lasting performance.

Our structural parts for rotavators are built to endure the rigors of heavy-duty farming operations. These components are designed to handle the high levels of stress and wear that come with soil cultivation, ensuring that the rotavators remain sturdy and effective over time.

We also supply various assembly and sub-assembly parts that contribute to the overall functionality of the rotavators. These parts are carefully crafted to fit seamlessly into the machinery, ensuring that the rotavators operate efficiently and with minimal downtime.

By supplying these essential parts to Maschio Gaspardo, Gloria Engineering Industries supports the production of high-performance rotavators that help farmers achieve better soil preparation and higher crop yields, ultimately contributing to more efficient and productive farming practices.

Gloria Engineering Industries is a reliable supplier of bracketry parts to leading automotive manufacturers TML (Tata Motors Limited) and M&M (Mahindra & Mahindra). These brackets are crucial for securing various components within the vehicle, ensuring stability, safety, and optimal performance.

We supply engine and transmission brackets that securely mount these critical components to the vehicle’s frame. Our brackets are designed to withstand the vibrations and stresses associated with engine and transmission operation, ensuring that these key systems remain stable and function smoothly throughout the vehicle’s life.

Our suspension and chassis brackets are engineered to provide strong and reliable support for the vehicle’s suspension system. These parts are vital for maintaining the vehicle’s ride quality and handling, as they keep the suspension components firmly in place, even under challenging driving conditions.

We also manufacture interior and exterior brackets that serve a variety of purposes, from holding interior panels and components in place to securing external parts like bumpers and lights. These brackets are crafted to ensure a perfect fit and long-lasting durability, contributing to the overall quality and appearance of the vehicle.

By supplying these essential bracketry parts to TML and M&M, Gloria Engineering Industries plays a key role in ensuring that their vehicles are built to the highest standards of quality, safety, and performance. Our commitment to precision manufacturing ensures that every bracket we produce meets the rigorous demands of the automotive industry.

Gloria Engineering Industries is a key supplier of radio mounting brackets to Reliance, a leading company in telecommunications and electronics. These brackets are designed to securely hold radio equipment in place, ensuring reliable and efficient performance in various applications.