01

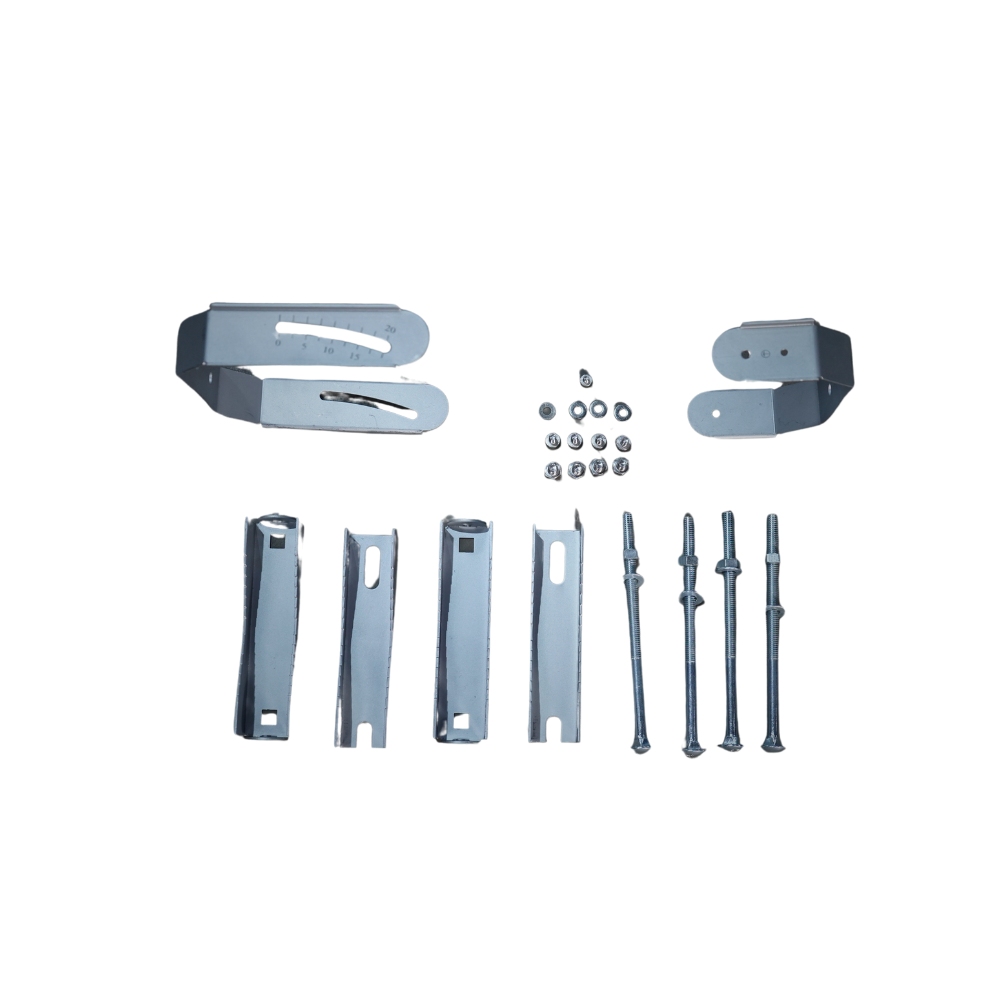

Sheet Metal Stamping

Our core competency lies in sheet metal stamping, where we produce precision-engineered metal parts using advanced stamping presses. With a variety of presses ranging from small to large tonnage, we can handle a wide array of materials, including steel, aluminum, and stainless steel. Our stamping processes are designed to produce high-quality parts with tight tolerances, ensuring consistency and reliability in every component.

02

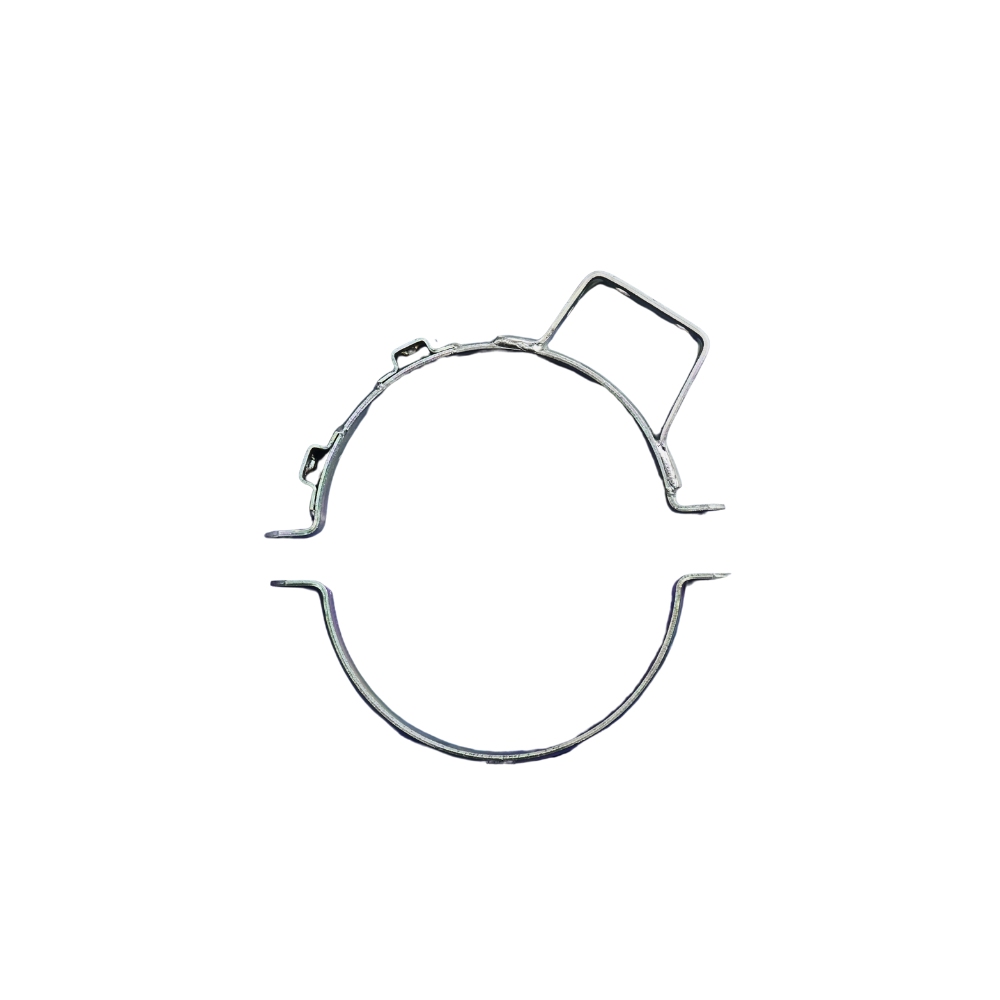

Welding Assemblies

We specialize in welding assemblies, providing robust and durable welded structures for various applications. Our skilled welders are proficient in a range of welding techniques, including MIG, TIG, and spot welding, allowing us to create complex assemblies with precision. Whether it’s a small bracket or a large structural component, we ensure each weld meets stringent quality standards, offering strength and longevity in the final product.

03

Machining Parts

Our machining capabilities complement our stamping and welding services, enabling us to produce finely detailed and accurately machined components. We utilize CNC machining centers that offer high-speed and high-precision operations, ensuring that every part is crafted to exact specifications. This capability allows us to provide complete solutions for clients who require additional machining after stamping or welding processes.

04

Coating and Surface Treatment

To protect and enhance the appearance of our metal parts, we offer coating and surface treatment services. Our facility is equipped with advanced powder coating, electroplating, Zinc flake coating and anodizing equipment, providing a range of finishes that improve corrosion resistance, durability, and aesthetics. We work closely with clients to select the appropriate surface treatment that meets their specific requirements, whether it’s for functional protection or cosmetic appeal.